The spray booth

From professionals for professionals

- available immediately

TB - Gradient steht für Qualität

Planning | Manufacture | Assembly | Service

- Highly efficient technology

- Fast delivery & assembly

- Fair pricing

- Complies with all EC directives and standards

- Made in Europe / Italy

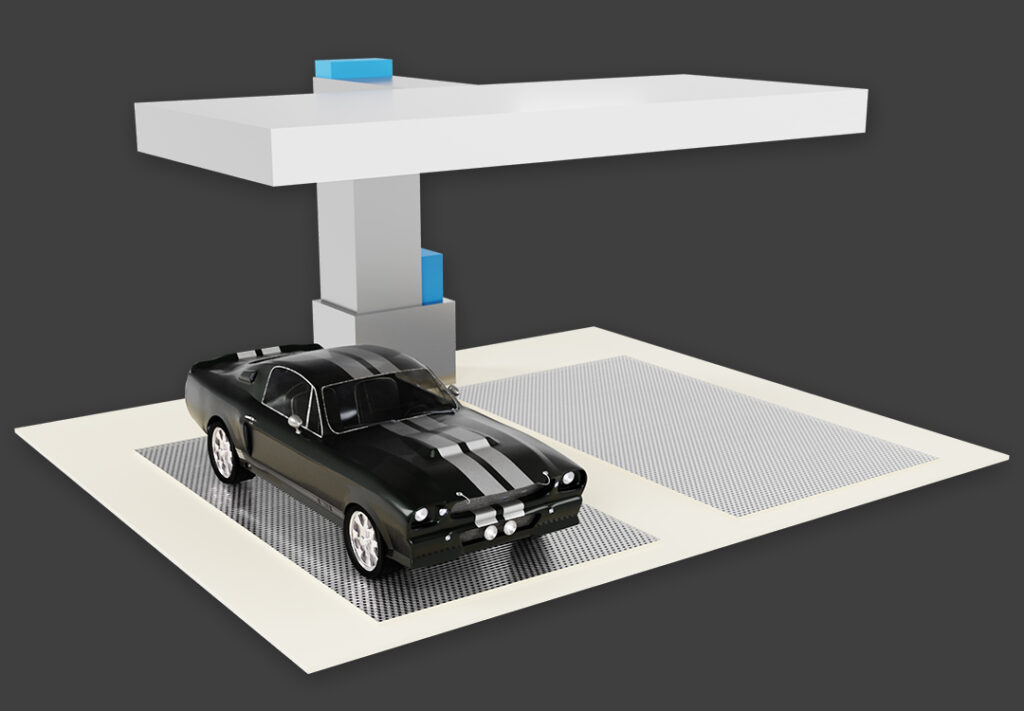

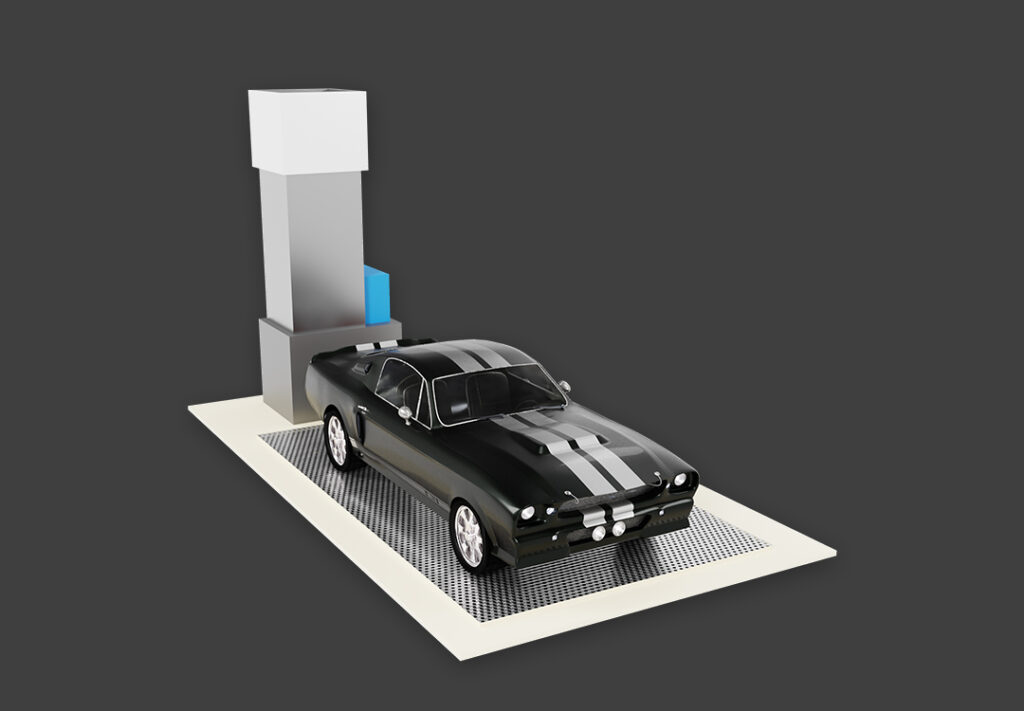

Our cabin in the 360 degree preview

The loading process can take a few seconds. (20 megabytes).

Get free advice now at: Tel: +49 (0) 33731 707 960

or make an appointment online

At a glance

TB - Gradient LACKIERKABINE

Item id: SB7428 One - Available immediately

Our Trommelberg Gradient spray booths are manufactured in Italy and are available in the following standard sizes:

Standard M - SB7428 One

L=7,0 m W=4,0m H= 2,74m

available immediately

Standard L - SB8428DB One

L=8,0 m W=4,0m H= 3,34m

approx. 4 weeks delivery time

SB8433DB

L=8,0 m W=4,0m H= 3,34m

approx. 4 weeks delivery time

SB48528DB

L=8,0 m W=4,5m H= 2,74m

approx. 4 weeks delivery time

- Total number of floor gratings: 35 galvanized gratings with a load of up to 500 KG per wheel mounting point

- 3-fold main access door with included service door, in white color inside and grey color outside

- Side door with safety glass window

- 340 mm high metal frame for cabin construction

- 8 luminaires with 32х58 W highly efficient triphosphor neon tubes from the XL series, daylight, IRC 85

- Air Blue 2.0 200KW gas surface burner

- 2 х 7.5 kW - V-belt driven drum fans

- Integrated "Easy Control" system control

- Filter set

- Corner shelf for tools

- Movable suspended painting stand

- Color-coded pressure gauge indicates the pressure inside the cabin

- Safety thermostat with manual reset

- Minimum pressure switch

- High-pressure circuit breaker

- Flow protection sensors for controlling the air flow

- Audible / visual alarm on the control panel

- Emergency lighting kit with visual alarm

- 2 Emergency exit safety instructions

- 2 locking devices for access doors

- Corner lighting: Set of 4 elements, 928W, Art. CL4458

- Fan-assisted gas burner with heat exchanger system

- Ramps

- Integrated system control "Premium Control"

- Soft start

- Air ducts

- Propane tank with house connection

- Paint spray guns

- Anti-static guns

- Lifting platforms

- Miscellaneous consumables

- Sprayable cabin protection film

Dimension:

Inside (LхBхH)

7000 x 4000 x 2760 mm

Outside (LхBхH)

7160 x 5010 x 3740 mm

3-part main door (BхH)

2700 x 2700 mm

Heating/ventilation unit:

Motor power supply air

7.5 kW

Motor power exhaust air

7.5 kW

Heat output

220 kW

max. air volume during the painting phase

24000 m³/h

max. temperature during the painting phase

30 °С

max. temperature during the drying phase

80 °С

max. oil consumption (at 20°С)

19 kg/h (15°E 10200 Cal/kg)

Energy supply:

17 kW

Electrical connection

Power consumption lighting

1856 W

- The spray booth is delivered partially finished. This means that it can be assembled in a maximum of 40 working hours.

- Thanks to a highly efficient 4-way heat exchanger, the booth ensures painting work at the highest quality level - even during the exhaust air phase and thus allows comfortable working conditions throughout the year.

- Or say goodbye to the conventional heat exchanger and opt for the even more efficient technology offered by the gas surface burner with almost 100% combustion efficiency. More is not possible!

- Four-stage air filtration: pre-filter in pocket format according to Eurovent EU4/G4, high-efficiency ceiling fine filter of class F5/EN779, two-stage paint-stop filter Eurovent EU3 + Eurovent EU4 (as part of the exhaust air filter), post-filter in pocket format according to Eurovent EU4/G4

- Cabin lighting: more than 1500 LUX!

The spray booth complies with the following guidelines and standards:

• 2006/42/CE, Machinery Directive

• 2014/35/UE, Low Voltage Directive

• 2014/30/UE (Electromagnetic Compatibility Directive), Electromagnetic Compatibility

Compatibility Directive 2014/34/UE ATEX Directive, in accordance with the European Standard EN13355 par. 5.8.2 - 5.8.2.1 - 5.8.2.2.

The SB7428 spray booth is assembled from 40 mm pre-assembled system panels. All panels are made of pre-painted double steel sheets and self-extinguishing polyurethane insulation materials with excellent thermal-acoustic properties.

The cabin is supplied fully painted inside and out. To ensure maximum safety for the user, all windows are fitted with shatter-proof safety glass and all doors are equipped with spring-operated door locks. A corner shelf for work equipment and a movable suspension system for individual components make the painter's work much easier.

The spray booth is equipped with a very efficient ceiling filter of category EU5. The ceiling lighting, which is angled towards the work surface, consists of neon tubes from the XL series (IRC 85) and fully illuminates the work area with maximum brightness and a neutral color temperature. Perfect painting results and the best possible conditions for color matching are guaranteed with the SB7428!

The spray booth can be installed both above ground and at ground level. The prerequisite for ground-level installation is a prior foundation excavation of 340 mm depth. The booth floor is fully equipped with galvanized gratings that can easily withstand a load of up to 800 kg per tire mounting point. All floor elements are made of galvanized steel.

Two-stage filters consisting of an EU3 and an EU4 layer are located under the galvanized grilles. Such a filter structure provides effective protection against contamination of the exhaust air fan and ensures high efficiency of the ventilation system.

The SB7428 spray booth is equipped with two radial fans with explosion-proof 7.5 kW electric motors. The forward curved blades of the fan ensure high efficiency. An EU4 pocket prefilter is installed directly at the fan inlet.

The design of the spray booth allows operation during both the exhaust air phase and the recirculation phase. It is also possible to control the pressure regulation in the booth manually by means of a control flap installed in the exhaust air duct. During the recirculation phase (partial air exchange), optimum air exchange parameters maintain a constant temperature on the paint surface. The spray booth achieves a high level of resource efficiency and economy by constantly circulating the heated air through the booth space.

The "EASY CONTROL" control unit is integrated into the front of the spray booth. It contains a temperature controller for painting and drying phases, a clock for the drying phase and an operating hours counter. The system also has an automatic heating and cooling mode.

The SB7428 spray booth is delivered in the form of pre-assembled elements and reduces the time required to assemble the booth by 50% compared to traditionally assembled booths.

Cabin construction

Mehr von TB - Gradient

Technologische Weiterentwicklung in jedem Aspekt - unsere Vorbereitungszonen

Wir sind TB - Gradient

TB – GRADIENT specializes in the manufacture and international distribution of workshop equipment.

Founded in 2003 and based in Trebbin near Berlin, the company has quickly developed into an internationally renowned and respected company with its extensive and high-quality product range.

The success of TB – GRADIENT is sustainable and is based on the following pillars:

- We are a team of experienced specialists

- We focus uncompromisingly on the needs of our customers

- We know the current trends in the industry

- We react quickly to important market innovations

- We ensure the quality of our products throughout the entire production chain

In order to continuously develop the TB – GRADIENT brand and offer our customers a modern and high-quality product range, we invest up to 10% of our profits in the further development of our products every year.

It is important for us to retain responsibility along the entire value chain. This is the only way we can guarantee that our high standards are maintained, from product design and production through to installation at our customers' premises.

Our product range offers the right solutions for the needs of a modern workshop. In addition to our state-of-the-art tire changing machines and computer-aided balancing machines, we are specialists in paint booths and body shop accessories.

In the tire changer sector, Trommelberg sells semi-automatic and fully automatic machines for cars and trucks.

Our high-precision balancing machines for cars, trucks and motorcycles meet even the most professional workshop requirements.

Other highlights from the Trommelberg product portfolio include exhaust hose systems and used oil extractors.

All our products are internationally certified and meet the highest technical requirements set in international workshop equipment.

For more information about our products and our company, please visit our store www.augusthandel-shop.com.

Get free advice now at: Tel: +49 (0) 33731 707 960

or make an appointment online